Foodec

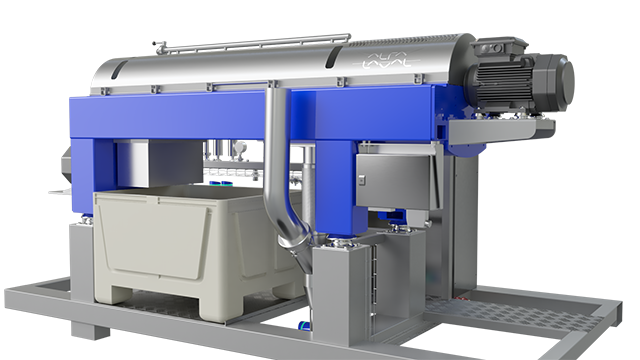

Alfa Laval Foodec dekantör santrifüjleri, yiyecek ve içecek ürünlerinin işlenmesinde verimliliğin ve kolay temizliğin oldukça önemli olduğu uygulamalar için idealdir. Protein ve süt ürünlerinden içeceklere, katı yağlara, bitkisel yağlara, nişasta ve endüstriyel fermantasyona kadar Foodec portföyü geniş yelpazeye sahiptir ve korumalı bir makine ile kesintisiz süreç gerektiren endüstriler için detaylı düşünülerek tasarlanmıştır.

Foodec dekantörlerinin gıda proseslerinde santrifüjü nasıl optimize ettiğini deneyimleyin

- Yüksek değerli nihai ürünler ve düşük atık yönetimi maliyetleri sağlayan yüksek performanslı separasyon

- Alfa Laval'in ileri teknolojisi ve akıllı kontrol sistemi ile kolay ve hızlı CIP temizliği

- Alternatif teknolojilere göre önemli ölçüde daha düşük güç tüketimine sahip enerji tasarruflu çalışma sistemi

- Kesintisiz işletim, yüksek kaliteli malzemeler, yenilikçi tasarım ve iyi düşünülmüş önleyici hizmetler sayesinde düşük bakım maliyetleri

- Farklı uygulamalara ve hammaddelere uyum sağlamak için yüksek operasyonel esneklik

Maksimum verim için optimize edildi

İki veya üç fazlı konfigürasyonlarda mevcut olan Foodec dekantör santrifüjleri, verimi, ekstraksiyon oranlarını, kek kuruluğunu ve sıvı berraklaştırılmasını en üst düzeye çıkarmaya yardımcı olur. Uygun gıda santrifüjü modeli, ham madde bileşiminize ve proses gereksinimlerinize bağlı olarak mümkün olan en iyi performansı sağlar. Alfa Laval'in yiyecek ve içecek işleme proseslerine yönelik dekantör santrifüjleri, değişken besleme hızlarını, katı madde konsantrasyonlarını ve sıcaklıkları yönetebilme yeteneği sayesinde, değişen üretim ihtiyaçlarına kolayca uyum sağlar.

Sonuç odaklı inovasyon

Onlarca yıllık uzmanlığa ve sürekli yenilenen yapıya sahip olan Alfa Laval santrifüjleri, zorlu ortamlarda bile sağladıkları kolaylıkla, verdikleri güvenle ve uzun ömürlü hizmetleriyle tanınır. Ayrıca proteinler, atık tahıllar ve yağ fraksiyonları gibi değerli yan ürünlerin geri kazanımını da optimize ederek, israfı azaltırken mevcut süreçlerden yeni gelir akışları oluşturmanıza yardımcı olurlar.

Fark yaratan özellikler

Bugün ve yarın karşılaşacağınız zorlukların üstesinden gelmek için ihtiyacınız olan her şey

Benzersiz Alfa Laval özellikleriyle, gıda uygulamaları için dekantör santrifüjümüz, gıda endüstrisinde gelişmiş verimlilik, güvenilirlik ve bakım kolaylığı sunar. Alfa Laval'ın benzersiz özellikleri, özel ihtiyaçlarınızı karşılamak için tasarlanmıştır ve optimum performans ve maksimum çalışma süresi sağlar.

TrueStainless™

Uzun süreli hijyen için paslanmaz çelik

TrueStainless™ teknolojisi, dekantör santrifüjünüzün aşındırıcı ortamlara maruz kalabilecek şase ve diğer kritik bileşenlerinde tamamen paslanmaz çelik kullanımını garanti eder. Bu sayede maksimum hijyen sağlanırken, ekipmanınızın uzun ömürlü ve dayanıklı olması güvence altına alınır.

PondCtrl

Çalışma esnasında ayarlanabilir hazne derinliği

Dekantör santrifüj hazne derinliğinin hızlı ve doğru şekilde ayarlanması, maksimum separasyon verimliliği, kolay temizlik ve sorunsuz çalışma için optimum koşulları sağlar.

SaniRibs®

Katı maddeleri uzaklaştırmanın temiz, etkili yolu

Eşsiz tasarıma sahip conta kaynaklı ribler daha fazla sürtünme yaratarak katı maddelerin daha iyi, daha verimli iletilmesini sağlar. Bu yenilikçi teknoloji aynı zamanda patojenlerin yoğunlaştığı noktaları da ortadan kaldırır ve kolay temizliğe olanak tanır; bu da daha uzun üretim süreleri, daha az manuel bakım ve daha iyi kazanç anlamına gelir.

FlightProtect

Konveyör kanatları için yüksek aşınma dayanımı

FlightProtect, her bir kanadın bütünlüğünü koruyan ve hizmet ömrünü uzatan, konveyör kanatların yönelik aşınmaya karşı özel koruma kaplamasıdır.

SaniFeed

Hijyenik uygulamalar için optimize edilmiş besleme bölgesi

Eşsiz dizayna sahip SaniFeed besleme bölgesi, ürünün hassas bir şekilde hızlanmasını ve minimum türbülansı sağlayarak düşük güç tüketimi sağlar. Pürüzsüz yüzeyler ve keskin köşelerin bulunmaması, hızlı ve etkili temizliğin yanı sıra maksimum çalışma süresi ve yüksek düzeyde hijyen sağlar.

PondCtrl – Çalışma esnasında ayarlanabilir havuz derinliği kontrolü

Havuz derinliğini gerçek zamanlı olarak düzenleyen ve otomatik çözüm olan Alfa Laval PondCtrl ile gıda santrifüjünüzün kontrolünü tamamen elinize alın. Katı madde tahliyesinde sıvı taşmasını önlemek, temizliği optimize etmek ve hammadde değişikliklerine uyum sağlamak üzere tasarlanan PondCtrl, daha yüksek çalışma süresi, daha iyi verim ve tutarlı ürün kalitesi sağlar.

- Otomatik havuz derinliği ayarı sayesinde sorunsuz başlatma ve durdurma özelliği

- Ürün kalitesinde üstünlük ve proses tutarlılığı için optimize edilmiş separasyon

- Sürgülü kapaklara gerek olmadan sıvı taşmasını otomatik olarak önler

- Disk çıkışıyla donatılmış, yeni ve mevcut dekantörlerle uyumlu

Dekantörünüz çalışırken prosesinize gereken hassasiyette bir ayar yapın. Gıda işlemede separasyon, tat ve verimlilik arasında mükemmel denge sağlayarak optimum santrifüj kabiliyetine ulaşın. Bu durum, özellikle ince lif içeriğinin kontrol edilmesinin, ürün başarısını doğrudan etkilediği bira ve bitki bazlı içecek üretiminde oldukça önemlidir. PondCtrl ile ayırma parametrelerini anında kolayca ayarlayabilir, üretimi kesintiye uğratmadan içeceklerinizin ağızda bıraktığı hissi ve tadı en iyi şekilde sağlayabilirsiniz.

Bir gıda santrifüjü nasıl çalışır?

Alfa Laval'in yiyecek ve içecek işlemeye yönelik dekanter santrifüjünün benzersiz tasarımı, gelen beslemeyi verimli bir şekilde üç aşamaya ayırır: yağ, katı madde ve su.

Ürün, sabit bir giriş borusu aracılığıyla tamburun içine beslenir ve daha sonra bir giriş rotoru tarafından kademeli bir şekilde hızlandırılır. Separasyon, vidalı konveyörle donatılmış yatay silindirik bir tamburda gerçekleşir. Merkezkaç kuvveti, katı parçacıkların tambur duvarında anında çökelmesine neden olur.

Konveyör tamburla aynı yönde ancak farklı bir hızda döner ve katı partikülleri konik uca doğru iletir. Daha hafif olduğu için katı veya sıvı yağ içeriden akarak yol alır, katılar tamburun dışına doğru hareket ederken sıvı ortada kalır. İki sıvı faz da titreşimli bir filtre aracılığıyla ilgili çıkış noktalarına iletilir ve daha sonra toplama tanklarına boşaltılır.

Değer katın – Havuz derinliği ayarı artık çok kolay

Alfa Laval Foodec tasarımı, akışı iyileştirmek için dar bir açıklıktan tamburun içindeki hidrolik basıncı artırır. Sıkıştırılmış ve susuzlaştırılmış katı maddeler, konik ucun küçük çaplı açıklıklarından tamburu terk eder. Separasyon, haznenin silindirik kısmının tüm uzunluğu boyunca gerçekleşir ve arıtılmış sıvı, bir ayırma diski (dahili merkezcil pompa) aracılığıyla dışarı çıkar.

Geleneksel dekantörlerin, sıvı bileşenin katı madde çıkışına taşmadan önce belirli bir havuz derinliği sınırı vardır. Alfa Laval'in Baffle Diski bu sorunu ortadan kaldırarak, taşma olmadan daha derin bir havuz özelliği sağlar. Disk, sıvının geçişini önleyen katı bir conta oluşturur. PondCtrl sistemi, operatörlerin başlatma, durdurma ve temizleme sırasında sıvı seviyesini ve havuz derinliğini bir kontrol paneli aracılığıyla otomatik veya manuel olarak kolayca düzenlemesine olanak tanıyarak maksimum separasyon sağlar. Dolayısıyla ürün kaybı en aza iner. Hammadde bileşimindeki değişikliklere rağmen optimum ayrıştırmayı sürdürmek için havuz derinliğini kolayca hassas bir şekilde ayarlayın.

Gıda endüstrisi için Foodec dekantör santrifüjlerdeki suya temas eden tüm parçalar paslanmaz çelikten yapılmıştır. Kontrol sistemi, grafik kullanıcı arayüzü ve çoklu iletişim seçenekleri ile donatılmıştır.

Yiyecek ve içecek işleme proseslerinde dekantör santrifüjleri başarı öyküleri

Gıda işleme prosesinde gelişmiş santrifüjleme teknolojisi sayesinde üretiminizi iyileştirin

Prosesiniz en iyi mühendisliği hak ediyor. Özel Global Servis Ağımız, nerede ne zaman ihtiyacınız olursa olun, olsun parça ve yetkin uzmanlıkla sizi destekler. Foodec'inizin performansını yükseltin. Yiyecek ve içecek işlemede maksimum çalışma süresi ve verimlilik sağlayın.

Toplam sahip olma maliyetinizi düşürerek ve yatırım getirinizi en üst düzeye çıkararak gönül rahatlığı sağlamanıza yardımcı oluyoruz.

Uzaktan destek ve izleme gibi internet bağlantılı hizmetlerle servis aralıkları uzatılabilir. Bakım, onarım, durum izleme ve uzaktan destek bir Servis Anlaşmasında birleştirilebilir. Ayrıca Alfa Laval, sahadaki bakım personelleri için de eğitim programları sunmaktadır.

İhtiyaçlarınıza özel olarak hazırlanmış bir Servis Anlaşması teklifi için özel servis uzmanımızla iletişime geçin.

Yiyecek ve içecek işleme proseslerine yönelik ilgili ürünler

Size yardımcı olalım

Alfa Laval yıllardır gıda santrifüjü pazarında lider konumdadır. Uzmanlarımız benzersiz ihtiyaçlarınızı analiz ederek gereksinimlerinize ve bütçenize en uygun ekipmanı, konfigürasyonu ve hizmetleri önerebilir. Talepleriniz veya zorluklarınız ne olursa olsun, sizin için doğru ekipmana sahibiz.