FEUX

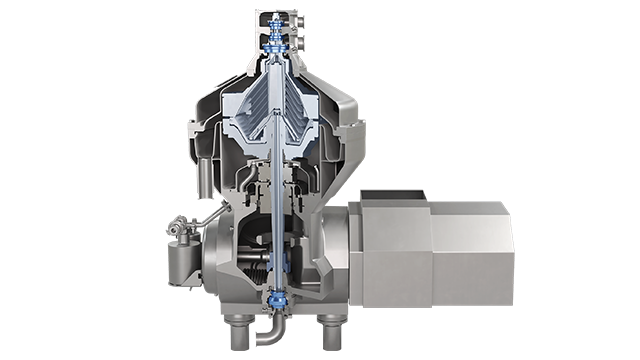

Alfa Laval FEUX seperatör, endüstriyel fermantasyonda optimum separasyon ve konsantrasyon verimliliği sağlamak için benzersiz tasarım özelliklerini bir araya getirir. FEUX seperatörler, konsantre katı maddelerin psödo-plastik özelliklerini kullanarak, çamurun santrifüj kuvvetine karşı tamburda kolayca akmasını sağlar.

Endüstriyel fermantasyon için FEUX seperatörlerin avantajlarını deneyimleyin

- Kendinden düzenlemeli vorteks nozulları, optimum konsantre kuruluk sağlar ve tıkanma riskini en aza indirir.

- Basınç altında çalışan kapalı sistemlerde katı fazın geri kazanımı minimum enerji tüketimiyle gerçekleştirilir.

- Yüksek operasyonel verimlilik; ekipman, tıkanma sınırına yakın koşullarda güvenle çalıştırılabilir.

- Otomatik CIP sistemli proses hatları için uygun- temizlik çevrimi boyunca yıkanmış katıların otomatik tahliyesini sağlayan opsiyonla mevcuttur.

FEUX Nozullu Santrifüjler Hakkında Daha Fazla Bilgi Edinin

FEUX seperatörler, merkezkaç kuvvetine karşı bile katı maddelerin tamburda kolayca akmasını sağlayacak şekilde tasarlanmıştır. Bu, kapalı, basınçlı ve hijyenik bir sistemde düşük enerji tüketimi anlamına gelir.

Disk tipi tamburun içinde katılar, konsantrat tüplerinden ve vortex nozullardan geçerek, paring tüpü aracılığıyla basınç altında tahliye edilir. Arıtılmış sıvı merkeze doğru hareket eder ve yine basınç altında tahliye edilir. Temizlik döngüleri sırasında katılar otomatik olarak tahliye edilebilir, bu da sistemi CIP hatları için ideal hale getirir.

Kendi kendini ayarlayan vorteks nozulları

Alfa Laval’ın vortex nozulları, besleme debisi ve katı madde içeriğindeki değişimlere otomatik olarak uyum sağlayarak tutarlı bir katı konsantrasyonu korur. Giriş ve çıkış basınçları, standart basınç düşüşleriyle karşılaştırılabilir seviyede olup, konsantre madde viskozitesinden bağımsız olarak stabil kalır.

Konsantre, nozül haznesine teğetsel olarak girer, tambur içinde döner ve merkezi çıkıştan çıkar. Bu tasarım, tıkanma riskini artırmadan tıkanma noktasına yakın kapasitelerde çalışmaya olanak tanır.

Komple sistem

FEUX üniteleri farklı boyutlarda sunulur ve separatör, motor, katı madde siklonu, şalter ve yol verici, kontrol paneli, vana grubu, debimetre, seviye göstergeleri, esnek bağlantılar ve diğer yardımcı ekipmanları içerebilir.

Bir sonraki separasyon ekipmanınızı test edin, doğrulayın ve ölçeğini büyütün

İster üretim hattınızı yenileyin ister bir fizibilite çalışması yapıyor olun, Alfa Laval doğru separatör ekipmanlarını güvenle seçmenize yardımcı olur. Danışmanlık, deneme ve kiralama opsiyonları için bizimle iletişime geçin.

Ar-Ge ve pilot projelere yönelik separatörlerimiz hakkında daha fazla bilgi edinin.

Separatörün Mucidiyiz

Separasyon teknolojisindeki yeniliklerimiz hakkında daha fazla bilgi edinmek ister misiniz? Aşağıdaki bağlantıya tıklayın. Alfa Laval, ilk disk yığın separatörünü icat etmesiyle birlikte bir asırdan fazla bir süredir santrifüj teknolojisinin gelişiminde öncü rol oynamaktadır. Bu süreçte edindiğimiz uzmanlığı sizlerle paylaşmaktan memnuniyet duyarız. Separasyon alanındaki gelişmeler ve Alfa Laval'ın devrim yaratıcı adımları hakkında daha fazla bilgi edinmek için Separator Innovator sayfamızı ziyaret edin.

Ayrıştırma teknolojisindeki yenilikler hakkında daha fazla bilgi edinin.