Alfie

Alfa Laval Alfie centrifugal separators remove oil, grease and solid particles from industrial coolants. They help prevent tool wear, reduce fluid consumption and lower your disposal costs.

Quick, continuous cleaning

- Can be linked to a bypass flow, ensuring less downtime for service

- Disc stack separators provide simultaneous, three-phase separation of oil and sludge

- Designed for operator convenience

- No machinery redesign required

The Alfa Laval Alfie range of compact, high-speed centrifugal separators minimizes operating costs by keeping coolants clean. Systems are fast and effective – helping improve end-product quality and reducing maintenance man-hours.

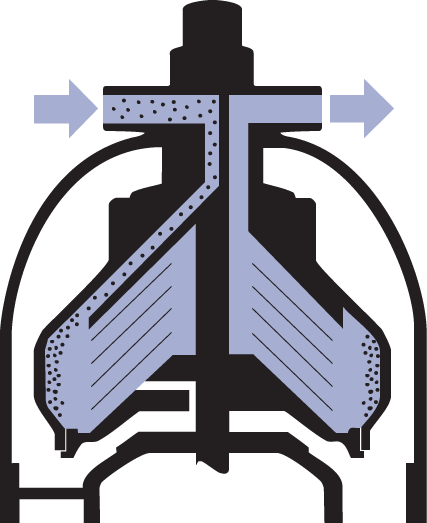

How it works

Alfie systems separate phases quickly by using a centrifugal force that's 5,000 times stronger than the gravity used in traditional settling tanks.

The centrifugal force presses heavy particles outwards against the separator walls. The disc stack forces lighter particles to follow the heavier ones instead of the liquid, making separation more precise and efficient.

Cutting fluid separation

Keeping your cutting fluids free from solid and liquid contaminants prolongs tool and fluid lifetime, which means a lower total cost of ownership and less service downtime.

Wash liquid cleaning

When it comes to cleaning wash liquids, the replacement process can be costly thanks to disposal and downtime. With efficient separation, you can maximise productivity and efficiency for longer.

Contact us

If you want to find out more about cutting fluid separation, fill in the form and one of our experts will be in touch soon.