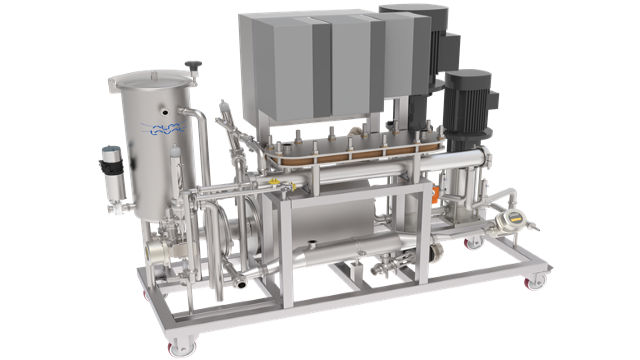

PilotUnit Multi

The Alfa Laval PilotUnit Multi is a multipurpose system with a broad selection of options that makes it possible to test all different kinds of membrane filtration products for microfiltration, ultrafiltration, nanofiltration and reverse osmosis in batch or semi-batch mode. It is an ideal tool for easy and reliable scale-up of processes or even small-scale production.

Fully integrated, space-saving and state-of-the-art filtration system with broad selection of options

- Easy to use – fully integrated system on a wheeled stainless steel structure. Data logging included and easy access via USB

- Compact and robust – comprises housing for single 3.8" spiral membrane, 40 l tank, pump, heat exchanger, valves, instruments and control system

- Low hold-up volume for high product concentration and minimal test media amount

- Flexible – pump system can handle low to high viscosity solutions and operates with the whole range of feed spacers (30-80 mil).

- Adaptable – suitable for pHt™ membranes with high temperature and pH tolerance

Nasıl çalışır

The Alfa Laval PilotUnit Multi comes as a skid-mounted unit and includes all necessary instruments, equipment and prefabricated piping ready for operation. All you need to do is to install and connect to the product feed, utilities and the power supply.

The product enters the tank via the feed valve (with level control). It is then pumped to the membrane filtration stage where the system automatically adjusts the pump speed and maintains the required cross-flow rate to reduce fouling and ensure the smooth concentration of your product.

The operator can adjust the controllers from the MemProC® PLC-based control system which includes a data logging system for the unit transmitters. The data can be downloaded to a USB.

Membran filtrelemenin arkasındaki temel prensip, bir sıvıyı iki farklı akışkana ayırmak için yarı geçirgen bir membranın kullanılmasıdır.

Sıvının membran yüzeyi boyunca çapraz akışta pompalanmasıyla membranın gözeneklerinden daha küçük bileşenlerin geçmesine izin verilir. Oluşturulan pozitif bir basınç sayesinde istenen permeat formu yakalanır.

Gözenek boyutundan daha büyük herhangi bir bileşen geçemez ve çökelti kısımda geride kalır. Spiral sarımlı membranın yüzeyi, membran yüzeyine paralel hareket eden sıvı akışının kuvveti sayesinde tıkanıklıklardan korunur.