Greensboro'daki T.Z. Osborne Su Geri Kazanım Tesisi, Alfa Laval Aldec G3 ile çamur susuzlaştırma kapasitesini iki katına çıkardı - yarı yarıya daha az güçle

Kuzey Carolina eyaletinin Greensboro şehrinde bulunan T.Z. Osborne Su Geri Kazanım Tesisi, uzun süredir şehrin atık su arıtma altyapısının temel taşı olmuştur. Yirmi yılı aşkın bir süredir çamur susuzlaştırma santrifüjleri kullanan tesis, kapsamlı yenileme çalışmaları veya kesinti süresi olmadan verimi artırmak, işletme maliyetlerini düşürmek ve giderek katılaşan deşarj yönetmeliklerine uymak için modern bir çözüm arayışına girmiştir. Eskiyen çamur ekipmanının Alfa Laval G3 dekantör santrifüjleri ile değiştirerek gerekli gücün yarısı ve daha az polimer kullanımı ile debiyi iki katına çıkarmıştır.

TARİH 2025-10-16

Since opening in 1984 with a capacity of 20 MGD, the facility has undergone a series of strategic upgrades to meet growing demand and evolving environmental regulations. By 2021, T.Z. Osborne had expanded to a capacity of 56 MGD - a nearly threefold increase. Although the facility initially intended to replace its 25-year-old sludge dewatering decanters through an open bid process, the project was reframed after engaging with Alfa Laval’s water separation experts, Mark Schlitzkus and Sipke Verbeek.

Turnkey delivery to compress cost and time

The consultative approach of Alfa Laval’s experts addressed mechanical and process questions, supported by reference visits to similar installations. After thoroughly assessing the needs of Greensboro’s water reclamation facility, Alfa Laval proposed partnering with an experienced integrator and managing equipment and installation as a single package - reducing engineering overheads, implementation risk and total cost of ownership. Crucially, this approach enabled two decanter installations within a budget originally scoped for one, while also shortening the project timeline.

Alfa Laval developed a proven solution for our centrifuge needs. Seeing the solutions at several west coast installations helped my team better understand the unique opportunity for our sludge dewatering. We are now able to feed our incinerators with one centrifuge where in the past it took two. Heyward’s and Alfa Laval’s management of the project made this one of the best solutions we have experienced at TZO,” comments a representative from T.Z. Osborne Water Reclamation Facility.

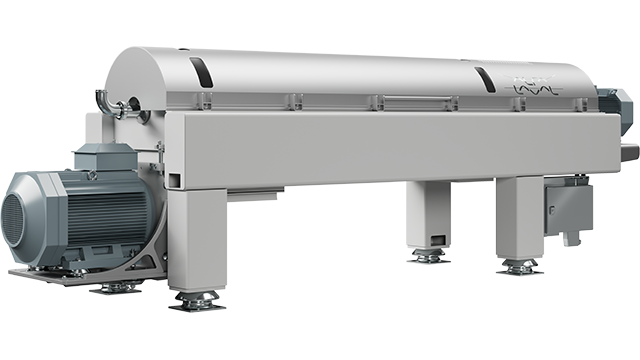

The plant selected Aldec G3 sludge dewatering decanters compact, high-performance machines engineered for low energy consumption and minimal operator intervention. Key feature innovations include SuperPond that enables a deeper pond for higher throughput and lower power, and PowerTubes that recover kinetic energy and further reduce energy use.

Results

- Flow capacity doubled per unit without expanding the municipal footprint, enabling operational flexibility across sludge management steps.

- Power consumption halved compared with the plant’s older units, supporting the city’s energy‑reduction goals.

- Polymer usage reduced, further lowering operating costs and environmental impact.

This was one of the best projects I have worked on in my 40 years in the business. It certainly had the right team in place on Alfa Laval’s side. I would advocate for that team on any retrofit,” says Tim Bishop, Regional Manager, Heyward Inc.

Öne Çıkan Teknolojiler

Alfa Laval Hijyenik eşanjör ürün grubu ile proses hijyenini ve ürün güvenliğini bir üst seviyeye taşıyın. Bu premium plakalı ısı eşanjörleri serisi, proses hijyenini ve enerji verimliliğini optimize eder. Hijyenik uygulamalar için özel olarak geliştirilmiş olup, olağanüstü performans ve verimlilik gerektiren gıda, içecek, ilaç ve diğer üreticiler için karbon ayak izini azaltırken hijyen seviyesini üst noktaya taşır.