Accurate troubleshooting wins a coveted award for a joint BASF and Alfa Laval team

When the chemical company BASF had to replace a pair of worn out heat exchangers at their Antwerp Caprolactam plant, it seemed like an ordinary project. They designed an installation based on AlfaVap heat exchangers that offered an acceptable payback period.

DATE 2025-12-11As soon as we identified the problem, Alfa Laval was right there helping us to solve it in record time.”

- BASF project leader Sven Fastré.

When the chemical company BASF had to replace a pair of worn-out heat exchangers at their Antwerp Caprolactam plant, it seemed like an ordinary project. They designed an installation based on AlfaVap heat exchangers that offered an acceptable payback period. But when unforeseeable difficulties developed, BASF learned the real value of Alfa Laval’s long experience and service-minded approach.

The challenge

The old heat exchangers were used to concentrate ammoniumsulphate, a by-product in the Caprolactam-making process. In addition to replacing the heat exchangers, the team assigned to the project set out to maximize the reuse of wastewater and thus to recoup the cost of the investment through savings. From the start, BASF was faced with a number of constraints: The new installation had to be small enough to fit on the plant roof, so the old installation could function as long as possible. It also had to accept a two-phase mixture. And, to make use of excess steam, high heat transfer was a prerequisite.

The (only) choice

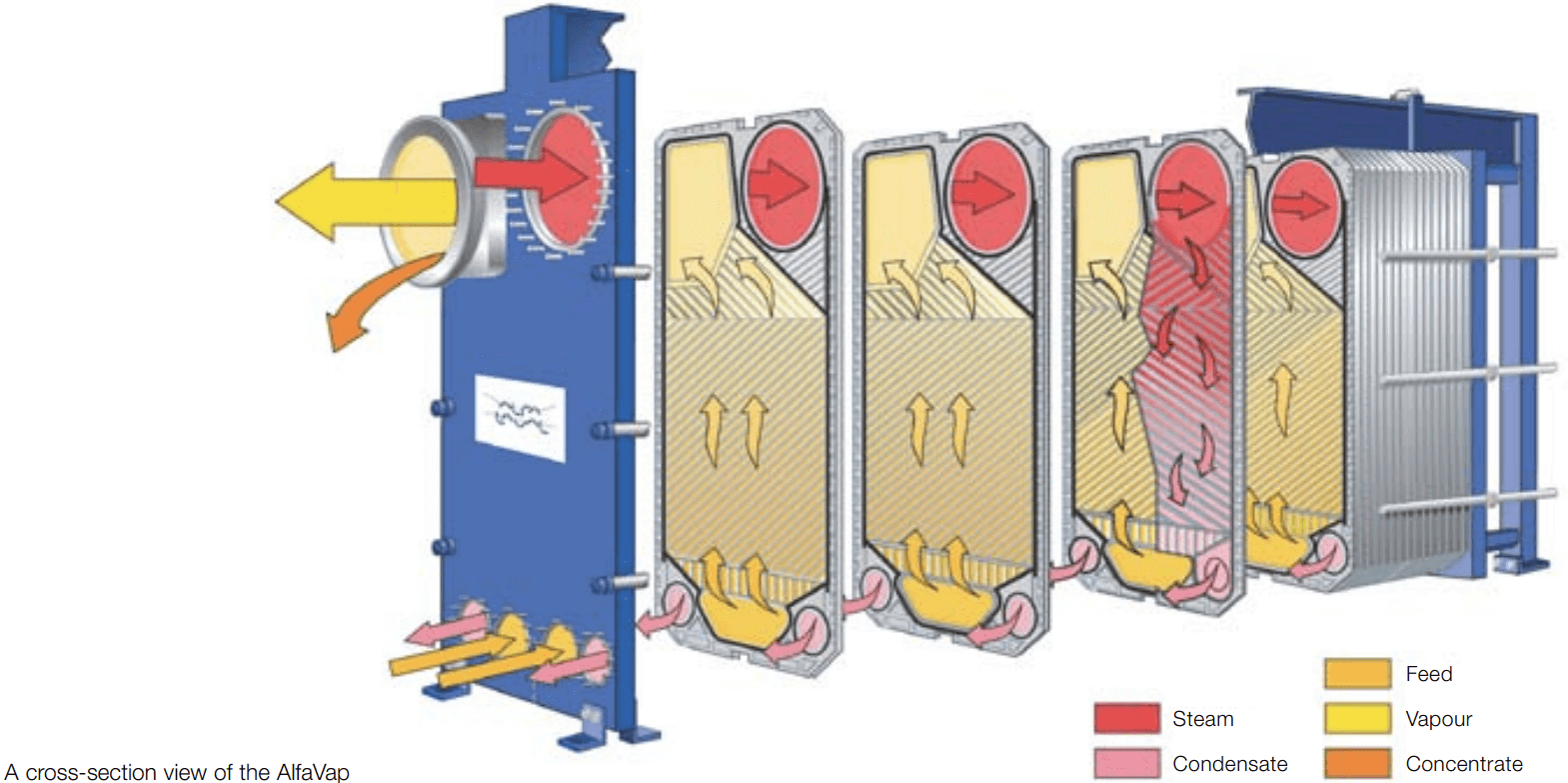

The BASF team decided to install two Alfa Vap heat exchangers from Alfa Laval. Their choice was simplified by the fact that the compact, extremely efficient, Alfa Vap’s were the only heat exchangers around that lived up to the requirements of the project.

We looked at other alternatives, of course, but only the Alfa Vap’s could handle the job.”

- Mr. Fastré

The clever concept

To achieve their goals, the BASF team redesigned their production line to optimize the reuse of water.

The commissioning – and the crisis!

The new system was completed right on schedule, and commissioning took place as planned. Unfortunately the start-up itself didn’t exactly go as expected. Mr. Fastré explains:

Something was wrong. The heat transfer wasn’t good enough. I picked up the phone, called Alfa Laval and told them: ‘your heat exchangers aren’t doing what they should.’ We checked the steam and condensate systems and the feeds and everything was clear. Alfa Laval said, ‘open them.’ Believe me, to stop production at that point was painful. But there was no choice.”

The - shift - correction

When BASF opened the units, they saw they had crystallization because of a problem with the wetting rate. As soon as the difficulty was identified, Alfa Laval put their people on a plane and sent them over to help.

Alfa Laval never even stopped to ask whose fault it was, they just came, and we put our heads together and worked around the clock to solve the problem. With the equipment we had on hand, Alfa Laval helped us put together a provisional solution, and we were up and running again within four days!”

- Mr. Fastré

The (happy) conclusion

Two years later, everything is functioning as planned. The ingenious design of the new plant – and the fast accurate troubleshooting by the BASF people and Alfa Laval – won the team an internal prize for innovation and troubleshooting.

“Seeing first hand the knowledge and the terrific service Alfa Laval brought to the rework has taught us the importance of taking advantage of such a skilled supplier in the project design phase. Nowadays, we involve potential suppliers in conceptual engineering from the start of a project. Because we want to take maximum advantage of their know-how and eliminate possible mistakes.”

- Mr. Fastré

Products

AlfaVap works magic on any company's evaporation and condensation costs. AlfaVap units take up much less expensive space, thus greatly reducing the investment cost.

Benefits

- Reduction in waste water flow, TOC load and N-load

- Increased recuperation of Caprolactam

- Reduction in demineralised water

- Reduction in maintenance

- Fast, effective troubleshooting by Alfa Laval when difficulties developed

Customer's voice

As soon as we identified the problem, Alfa Laval was right there helping us to solve it in record time.

Sven Fastré

BASF project leader

Sven Fastré of BASF and Daniel Arguelles of Alfa Laval deep in discussion in front of the flash vessel used in BASF’s ammonium sulphate concentration process.